The Crucial Role of WMS in E-commerce Fulfilment Centres

Discussing about WMS’s impact on e-commerce fulfilment centres, its evolving intelligence, and integration with warehouse operations, shaping the future.

An efficient warehouse or distribution centre (DC) is crucial for profitable e-commerce. While small sellers may manage in limited spaces, growing companies require more. The warehouse is where operations thrive, blending people, processes, and systems. Warehouse Management Systems (WMS) streamline tasks, from inventory tracking to order processing, aiding optimization, integration, and compliance.

Currently, the issue lies in the outdated nature of many WMSs. These on-premises systems weren’t crafted for modern e-commerce complexities, lacking scalability.

Complex e-commerce fulfilment demands increased automation and integration for sustained competitiveness. The evolution of WMS in this realm is anticipated to accelerate.

Integrating Intelligence and Automation – Strategies Beyond Adding More Staff

In envisioning the future role of WMS in e-commerce fulfilment centres, there’s a shift towards smarter management, leveraging advanced analytics, AI, and robotics to optimize operations amidst labour constraints, particularly significant in e-commerce environments where advanced intelligence is highly valued.

Fast-paced e-commerce operations are using indoor locating technologies to track workers and tasks more efficiently. There’s a new interest in RFID, especially in warehouses, driven by e-commerce’s growth.

RFID tags, originally for stores, are now considered for warehouse use. This progress is spurred by the rise in e-commerce sales. In the past, large companies shipped in bulk to stores, but now, orders often require individual packaging.

Companies need to determine when individual customers will receive their orders directly. High-volume operations require new strategies as adding more staff isn’t feasible anymore.

Improving Warehouse Operations through Software Integration:

Cloud computing, APIs, and interoperability have simplified communication between software systems. While older WMSs may struggle, newer systems are designed for compatibility.

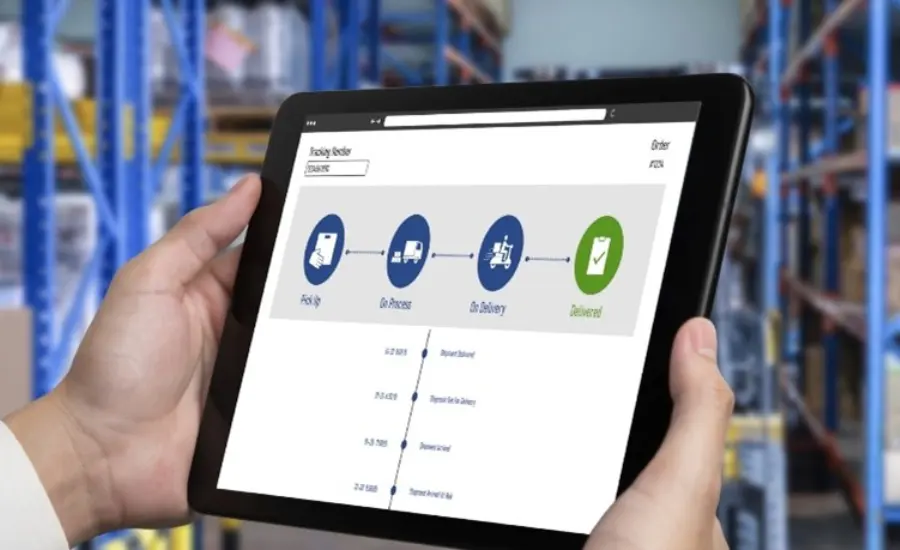

This trend is expected to improve warehouse operations, enabling comprehensive management from a single platform. It involves linking WMS with WCS and WES to create a closed loop system.

There’s still much work needed before integrating different systems becomes common. WMS handles orders, labour, and ERP inputs, coordinating with manual or automated labour. This requires complex system engineering.

Solving this requires various algorithms for software design interacting with different types of operations. WMS is now adapting to coordinate both manual and automated tasks, a new challenge.

WMS providers successfully addressed the issue by incorporating new functionalities or integrating with existing systems.

Managing operations using WMS:

When assessing the current state of e-commerce fulfilment and the advancements in WMS, it’s evident that when WMS collaborates with other systems, it acts as the primary decision-making hub for a bustling warehouse.

Businesses can utilize operations management tools to adjust labour allocation based on anticipated order volumes, even down to the hour, effectively distributing human and automated resources.

“Managing data across various warehouse zones is a challenge for companies. This aspect of operations management holds significant promise for the future.”

In conclusion, WMS technology enables seamless implementation of key customizations for better warehouse management in e-commerce, including third-party EDI interfaces, analytics, Locus Robotics integration, shipment optimization, and outbound planning enhancements.